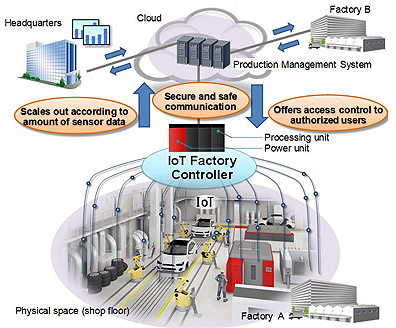

The system is designed to connect Mitsubishi’s e-F@ctory automation architecture with the cloud to tap into the emerging IoT ecosystem. Factories of the future are expected to become increasingly interconnected via the cloud to allow advanced production management.

At the moment, the e-F@ctory system offers real-time capabilities, security and reliability for manufacturing execution and quality management systems, but does not use the cloud.

The IoT factory controller will integrate with e-F@ctory to allow real-time connections between the shopfloor and the cloud. It will allow plant operators to analyse and visualise data graphically to achieve greater productivity and quality. It will also provide security to protect systems against data manipulation, unauthorised access and other cyber-attacks.

Mitsubishi expects predictive maintenance and diagnostics using large amounts of data to become an important part of future manufacturing operations. Increased data from sensors on production lines, and other sources, will expand the need for data-processing in factories. The new factory controller technology is designed to expand data-processing capabilities flexibly, due to its scalable structure.

Mitsubishi's IoT Factory Controller will link industrial sites via the cloud

In some cases, it will be necessary to establish cloud connections to equipment from several different manufacturers. To facilitate this, the technology will allow access to specific machines registered by users.

Mitsubishi has 13 patents pending for the new technology in Japan, and 11 internationally.