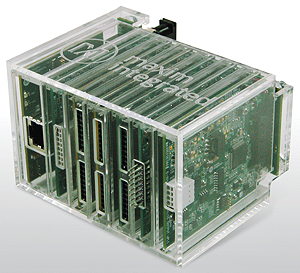

According to Maxim, one its PLCs containing six modules (a four-channel analogue input module, a single-channel analogue output module, an eight-channel digital input module, an eight-channel digital output module, a four-channel IO-Link master, and a dual RS-485 communications module) will fit in a box occupying 400cm3 (23in3).

It says that it has achieved this reduction in size using a “smart integration” philosophy that combines industrial system-level knowledge with a proprietary analogue process technology. This results in compact, high-performance digital input and output modules and power modules. It claims that the PLC’s footprint is ten times smaller than those of conventional modular PLCs currently on the market.

For example, Maxim’s four-channel analogue input card occupies a volume of about 2.7in3, compared to 27in3 for a traditional PLC equivalent.

The company adds says that its digital inputs can achieve power savings of 40–60% compared to standard discrete digital inputs. In addition, a power architecture based on synchronous rectification allows the PLCs to run up to 50% cooler than traditional systems that use non-synchronous rectification. This allows the PLCs to operate without cooling fans and for the I/Os to achieve higher densities.

Another of Maxim’s claims is that its digital outputs can process data 70 times faster than traditional designs because they use a special “push-pull” mode with a maximum 2µs delay. It says that most conventional digital inputs produce delays measured in milliseconds.

According to Maxim, its PLC will allow users to implement distributed Industry 4.0 systems using less power, with fewer parts and at lower costs. For example, a four-channel analogue input board costs US $39.

“Our customers can build smaller, faster, and more efficient industrial controllers that bring the vision of Industry 4.0 into the palm of their hands,” says Maxim’s executive director of business management, Jeff DeAngelis.

The PLC platform consists of five reference designs which can operate as stand-alone sub-systems. They can be configured and tested via USB link to a laptop.

Maxim claims that its micro-PLC has a footprint that is 90% smaller than conventional modular PLC designs

The high level of integration in the PLC system is said to cut component counts, improve reliability, and provide diagnostics that will help to cut maintenance costs and increase uptime.

To support the Industry 4.0 distributed model, Maxim has developed several other products that are interoperable with the Micro PLC platform. They include:

• a 24-bit, 10mW, delta-sigma analogue-to-digital converter with integrated PGA (programmable-gain amplifier), which is claimed to offer the highest signal-to-noise ratio and the lowest power in its class;

• a 2.4–5.5V, 5A input switch-mode power supply with an efficiency of 92%; and

• a tiny 4–60V, 100mA synchronous step-down DC-DC converter, that complies with the IEC 61131-2 PLC standard, and enables cooler operation.

Maxim specialises in developing analogue circuits that are smaller, smarter, and more energy efficient. It employs about 8,800 people worldwide and has annual sales worth around $2.4bn.