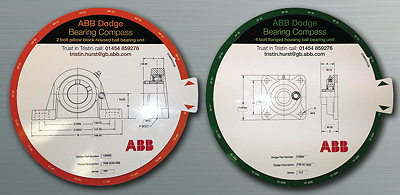

Called the “bearing compass”, the device lists all of the common bearing types and designations, and includes references and sizes of standard housed bearings. There are two versions: one for pillow block housed bearings; the other for two- and four-bolt flange housing ball bearings with standard shaft-mount inserts.

“It is important to have all the housing data and dimensions on-hand when replacing a bearing, as specifying an incorrect bearing can have a big impact on swap-out time and can quickly escalate machine downtime,” explains Tristin Hurst, ABB’s bearings product manager for the UK.

The ability to exchange bearings quickly and accurately is an important to minimise downtime for repairs and maintenance, because machines need to be up-and-running again as quickly as possible.

“Bearings installed in recycling, aggregates or mining equipment often need regular maintenance and can often fail as they operate in some of the harshest conditions,” Hurst adds. “This is why we developed the bearing compasses to make the specification and ordering of replacement bearings a straightforward task.”

The version for pillow block housed bearings contains data on ABB’s Dodge Setscrew ball bearings on one side, and the heavier-duty Dodge ISN spherical roller bearings on the other. The ISN bearings have an easy-on, easy-off adapter sleeve mounting, making them quick to install compared to standard housed bearings.

The Dodge two- and four-bolt flange housing ball bearings specified on the second bearing compass, are dimensionally identical to standard bearings and are interchangeable with most existing housed bearings.