SKF calculates that a 350kW version of its system could save 500,000kWh a year – equivalent to a 375-tonne reduction in CO2 emissions.

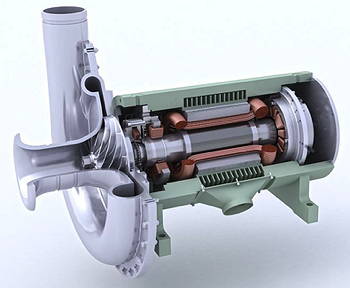

The system consists of a high-speed permanent magnet motor (PMM) rated from 75–350kW, using active magnetic bearings and controls. Unlike traditional induction motors, the PMM maintains efficiency at half-load and half-speed. The design also uses fewer mechanical parts than traditional aeration blower drives, reducing the need for maintenance, while built-in monitoring and diagnostics maintain high performance and reliability.

According to Vincent Megret, managing director of SKF Magnetic Systems, the new drive system “meets the demand for energy efficiency, and the need for reduction of maintenance and service costs, as well as the requirement to comply with air quality and safety standards.” He reckons that a 350kW version could pay for itself within a year “from energy savings alone”.