Research carried out at the University of Kassel in Germany has shown that pneumatic actuators consume 10.3 times more energy than electromechanical actuators and 4.4 times more energy than hydraulic actuators. The research, which included the cost of implementing or retrofitting an existing system, did not take into account air leaks, which can add another 50% to energy bills.

This is borne out by our own experience in the UK at a margarine manufacturer which operates five 110kW compressors. The company concluded that one of the compressors was there purely to maintain air pressure because of all the leaks in the several kilometres of air-lines around its plant. Operating the 110kW compressor on electricity costing 10p/kWh for 24 hours a day, 365 days a year, meant that more than £95,000 was being wasted every year.

It is difficult to quantify the total equivalent hole diameter for the holes in an air-line because often you don’t know where they are. Diagnostics personnel have to carry listening devices to detect hisses in the pipework and establish where the leaks are in order to seal them. Because the temperature of the air-lines always fluctuates, condensation forms and leaks occur. You can never find all of these leaks and even if you do fix them, they come back somewhere else.

Wasted energy

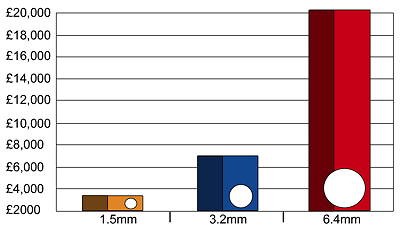

The German study estimated the total air leaks to be roughly equivalent to a 6mm diameter hole per km of pipework, costing £20,000 a year in wasted energy. Another study, conducted by University of Pittsburgh on continuous automotive welding guns, suggests that the energy cost of operating a servo-electric actuator is about a tenth of the cost of using pneumatic actuation – the equivalent of £470 instead of £4,700 a year.

The graph (above) shows the annual costs (in UK terms) of pneumatic air leaks for holes of different sizes, based on a constant air supply and energy costing 12p/kWh.

We also know that in power stations and process industries that use electric actuators to control fluid flows through pipes, their costs are about 10% those of using pneumatic actuation. Even pneumatics companies agree on this.

Pneumatic systems use air even when actuator motion is not needed. By contrast, electric actuators use energy only when it is essential. The longer the dwell cycle between moves, the larger the energy savings. Furthermore, air-lines and seals wear and split due to contamination and ageing, thus needing constant maintenance and replacement, often requiring many man-hours and headaches to repair the kilometres of hoses.

Another attraction of electric linear motion is that it is a clean technology and is therefore preferred in industries such as food, water, medical and pharmaceuticals. The aerospace and defence sectors already have a strategic vision to convert new programmes to all-electric actuation.

Air systems are difficult to control in terms of positioning and force due to seal stiction and overshoot. Furthermore, health and safety regulations state that machines should operate below 85 decibels at a distance of one metre, and electric actuators are much quieter than pneumatics.

Injection moulding

During the 20th century, hydraulic cylinders were the motion control devices of choice for injection moulding but now, when it comes to creating the precise, rapid motions that are needed in this application, electromechanical actuators with integrated servomotors are gaining ground.

Volumetrics, gate design and temperature control are key considerations and mould-makers use a host of tools to fill a mould quickly, after which time the mould has to be cycled. The speed with which the core can be moved in and out is critical. Traditional hydraulic cylinders are fast, but in most applications an electric actuator can enhance cycle rates significantly by allowing related operations to start sooner because it uses feedback loop control to monitor the core’s actual position and motion status in the controller constantly. In addition, the acceleration and deceleration rates can be greater with higher maximum speeds.

Longer tool life is an added benefit. Replacing a hydraulic cylinder with an electromechanical actuator almost guarantees a longer tool life. The actuator allows the core to be inserted faster without slamming the mould together violently, is a similar way to the positioning ride comfort mechanisms in passenger lifts.

Less stress on machinery means longer life – a mechanical principle that also applies to our day-to-day human experience.